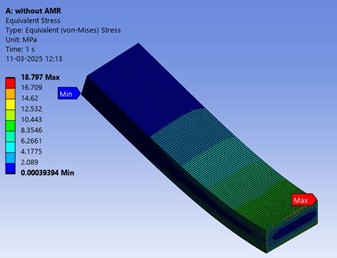

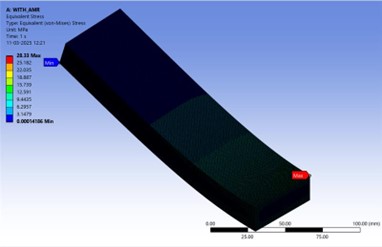

In engineering simulations, stress singularities pose a significant challenge. These occur in areas of a model, such as sharp corners or notches, where stress values can become infinitely large, leading to unreliable results. Addressing these singularities is crucial for creating accurate and safe designs.

One of the most effective ways to mitigate this issue is through local mesh refinement. By increasing mesh density specifically in high-stress regions, we can capture stress behaviour more precisely and avoid the exaggerated stress peaks that typically arise near singularities. In this post, we’ll explore how mesh refinement works, its role in overcoming stress singularities, and best practices for implementing it in your simulations.

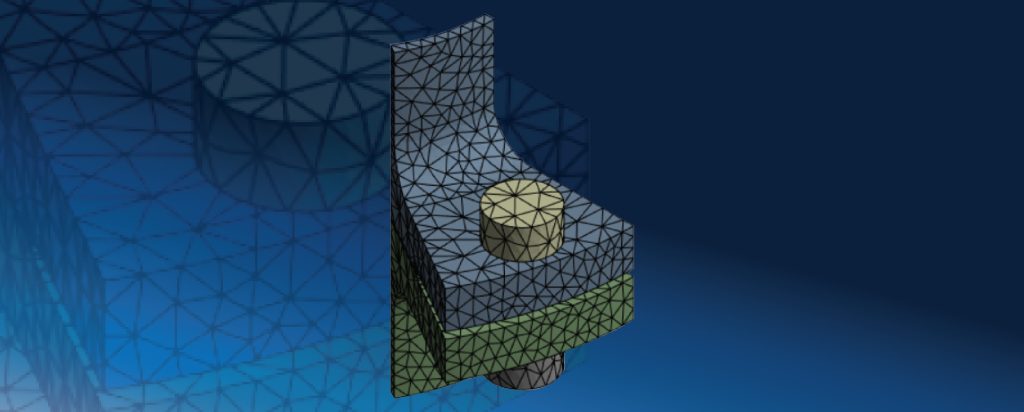

Local mesh refinement is a technique used in finite element analysis (FEA) to improve the accuracy of simulations, particularly in regions with complex stress behaviour. Instead of refining the entire mesh, which can be computationally expensive, this approach focuses on areas that are critical—like sharp edges, holes, or places with high stress gradients.

By identifying key stress-concentrated areas, using adaptive meshing, and ensuring mesh convergence, engineers can balance accuracy and computational efficiency. Tools like Ansys, available through CADFEM, make this process more streamlined, allowing for better design insights and more reliable simulations.