Improving equipment design and operational efficiency is essential for increasing plant productivity. In industries like steel, cement, and thermal power, even small inefficiencies in equipment layout or operational workflows can significantly impact overall performance. By focusing on optimizing equipment and addressing operational challenges, plants can achieve greater efficiency, reduce downtime, and enhance profitability. This is where Ansys Rocky comes in.

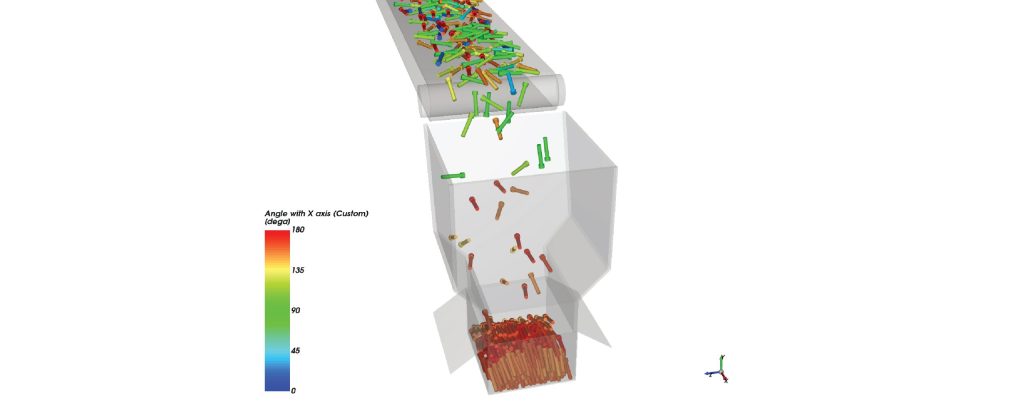

A standard plant circuit includes equipment for sizing materials, classification, and segregation, followed by conveyance systems. The processed material is ultimately subjected to heat in blast furnaces at steel plants, boilers at thermal plants, or kilns in cement plants.

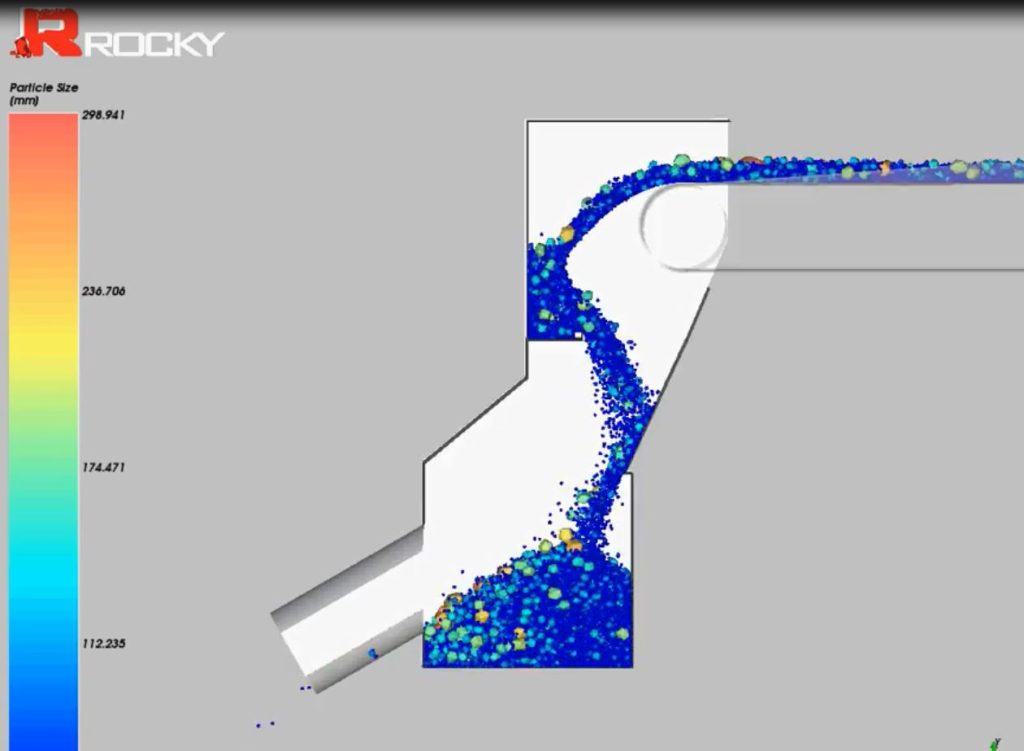

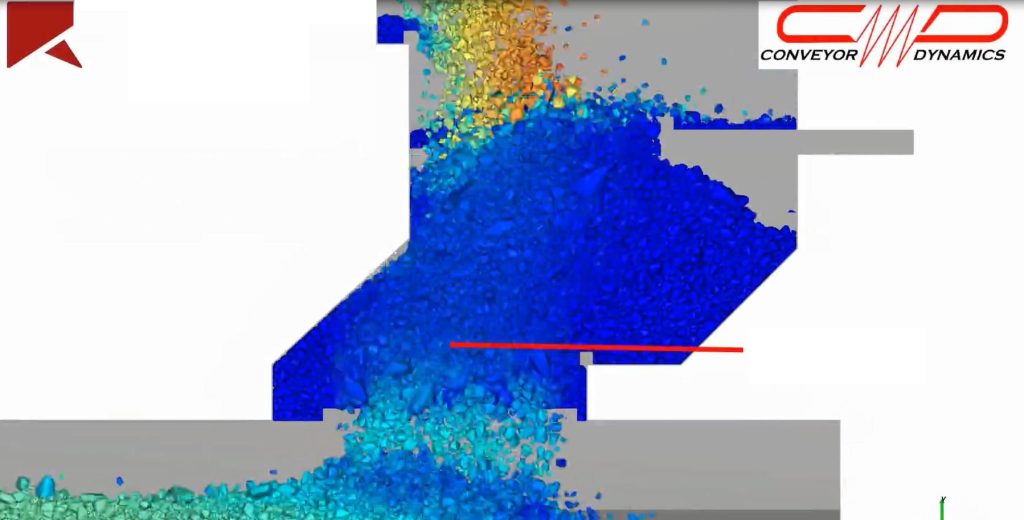

A decrease in tonnage handled per day by transfer chutes—due to blockages or material flow issues—can cause exponential losses, especially given the substantial number of chutes in any plant circuit.

Rocky, a powerful Discrete Element Modeling (DEM) software, provides comprehensive solutions for improving equipment design and operational workflows. Here’s how it addresses common plant inefficiencies:

By leveraging the Archard wear equation, Rocky predicts surface wear trends with high accuracy. Inputs like volumetric loss and material of construction (MOC) data allow engineers to schedule predictive maintenance, preventing unexpected downtimes.

Rocky can provide fragmentation ratios, enabling iterative analysis of crushing and grinding equipment performance. This data helps engineers refine equipment settings for optimal results.

Ansys Rocky is the only DEM tool capable of simulating water-based processes, such as slurry and moisture applications. This feature is invaluable for monitoring and optimizing sticky materials during rainy seasons.

Ansys Rocky can be calibrated to replicate exact site conditions, eliminating even the smallest deviations. This ensures that simulations align with real-world processes, enhancing accuracy and reliability.

Achieving higher plant efficiency requires addressing both equipment design and operational inefficiencies. While redesigning material processing equipment can be expensive, focusing on conveyance systems and optimizing workflows offers a more cost-effective approach. Rocky’s advanced simulation capabilities provide engineers with the tools needed to optimize equipment performance, predict maintenance needs, and tackle operational challenges. By leveraging Ansys Rocky, plants can achieve significant efficiency improvements, reduce costs, and ensure smoother operations across circuits.