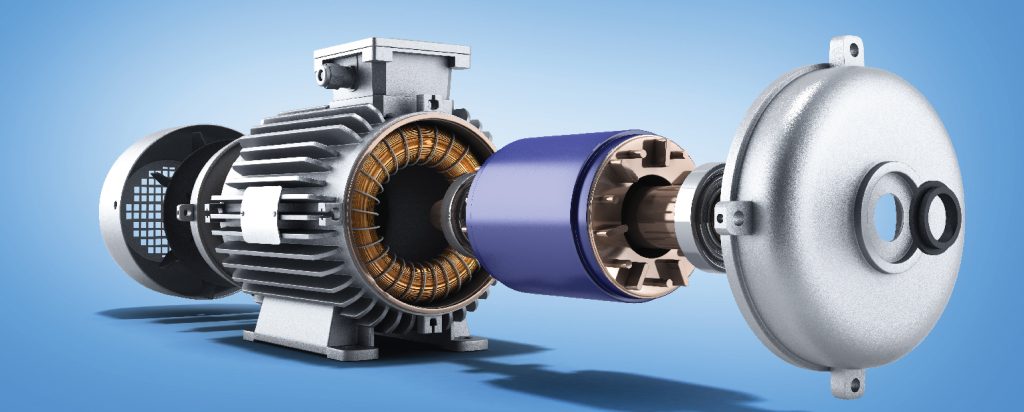

Electric motors (E-motors) account for a significant portion of global energy consumption, comprising 70% of the electricity used in the industrial sector. The Electric Vehicle (EV) market, projected to grow at a CAGR of 9.82% from 2024 to 2028, is further driving the demand for efficient motors. However, the low efficiency of conventional motors contributes to increasing energy demand, posing a significant challenge.

Figure 1 Single Transmon Design

Simulation tools play a pivotal role in addressing these challenges by reducing development time and prototyping costs while ensuring efficient motor design and optimization.

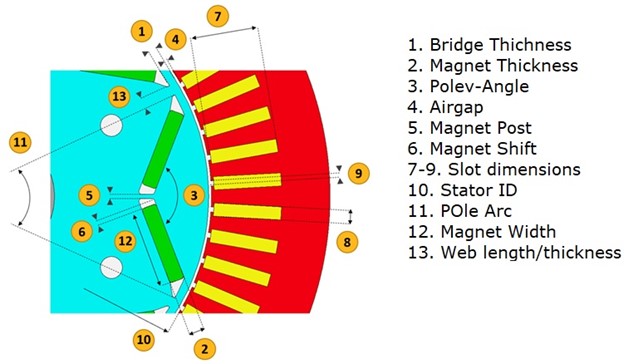

Fig. 1 : Variable Parameters considered for optimizing torque ripple

Optimizing permanent magnet materials and dimensions requires multiple iterations, which is impractical and costly with traditional prototyping methods. ANSYS simulation tools significantly contribute to the E-motor industry by offering reliable, economical, and efficient solutions for designing high-performance motors. By leveraging tools like MotorCAD and optiSLang, engineers can develop motors that meet performance parameters while reducing costs and development time, paving the way for sustainable and innovative technologies in the EV and industrial sectors.