Traditional inspection methods—such as visual microscopy, interferometry, or physical testing—can identify visible defects on a camera lens surface, but they often fail to predict how those imperfections affect optical performance under real operating conditions. Moreover, physical testing of multiple defect types or dimensions is time-consuming, costly, and may not replicate in-field environmental factors accurately.

Ansys SPEOS, an advanced optical simulation software, overcomes these limitations by allowing engineers to model, visualize, and quantify the optical effects of cracks and bids before any physical prototype is built. Using physics-based light propagation and material interaction models, Speos enables virtual testing of lens assemblies with controlled defect parameters (e.g., crack width, depth, orientation, or surface roughness)

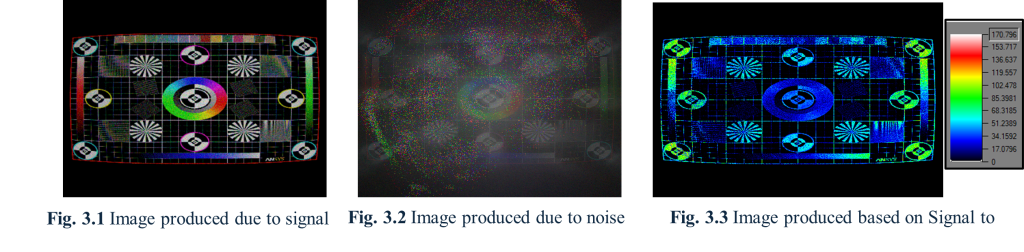

a. Image result of a physical camera, whose lens stack is without any defects:

c. Results of a physical camera, whose lens stack has a crack of width- 0.01mm:

The subtraction operation, in SPEOS tools, is a direct way to visualize the effect of cracks on the optical performance of the system.

It allows engineers to see which regions of the sensor are most affected and by how much, supporting decisions about design, material selection, or quality control.