In a rapidly evolving industrial landscape, businesses across sectors are under growing pressure to innovate while controlling operational costs. Simulation for industry has emerged as a vital tool to achieve these dual objectives. From manufacturing to logistics and healthcare to energy, simulation technologies empower organizations to make smarter decisions, build better products, and cut costs all before a single part is produced or a process is executed in real life.

By leveraging tools like industrial simulation software, digital twins, virtual prototyping, and advanced process simulation, modern enterprises are transforming the way they design, plan, and operate. This blog explores how simulation is becoming a catalyst for cost reduction and innovation across diverse industries.

However, businesses are overcoming these challenges by investing in upskilling programs, partnering with simulation experts, and adopting cloud-based or modular simulation platforms that scale with growth.

Looking ahead, simulation is becoming even more powerful through integration with emerging technologies:

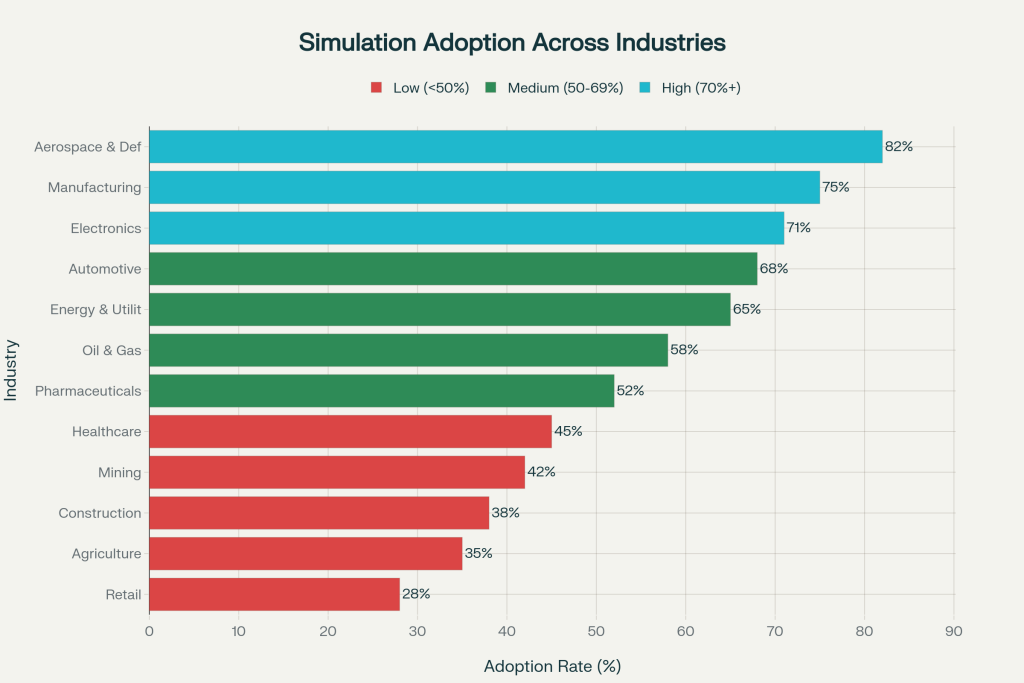

Simulation for industry is no longer a specialized tool—it’s a strategic imperative. From cutting costs through virtual prototyping to fueling innovation through digital twins and predictive analytics, simulation is helping companies across sectors work smarter, faster, and leaner. Simulation is not exclusive to manufacturing—it’s impacting a wide spectrum of industries” to provide a more complete picture of simulation’s universal applicability across all industrial sectors

Now is the time to make simulation a cornerstone of your digital transformation strategy.

Contact us Now