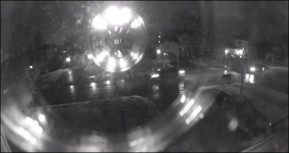

Optical simulation is transforming IR camera design by enabling precise analysis and control of stray light for superior imaging performance. When we talk about light pollution, most people imagine glowing cityscapes that obscure the stars. In infrared (IR) imaging and sensing, however, the term takes on a different meaning: stray light. This refers to unwanted energy—reflections, scattering, or ghosting—that enters IR camera sensors. The consequences can be subtle but critical: reduced signal-to-noise ratio, blurred thermal patterns, or distorted imagery that compromise both system performance and reliability.

For industries that depend on IR imaging—whether in security, aerospace, automotive, or industrial monitoring—stray light represents a common yet serious challenge. As IR technologies continue to expand into areas like predictive maintenance, surveillance, and autonomous systems, the demand for clearer, more accurate data has never been higher. Any degradation caused by stray light directly impacts efficiency, safety, and decision-making.

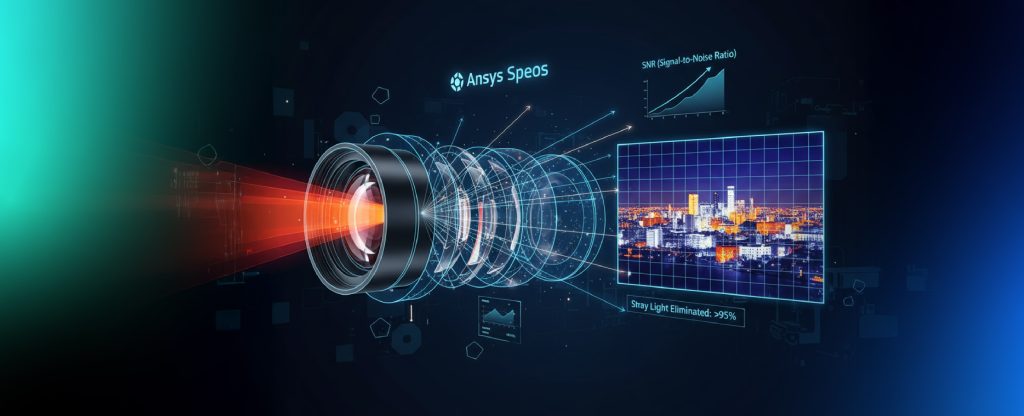

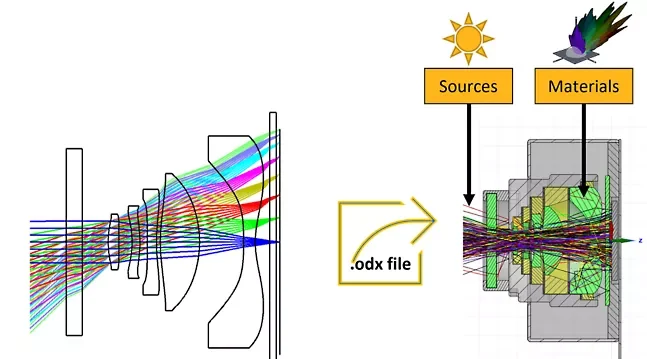

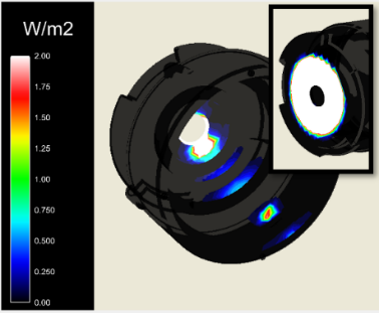

Optical simulation tools such as Ansys Speos, CODE V, and ImSym now make it possible to analyze and optimize IR camera performance virtually, long before the first hardware is built. These platforms allow the creation of digital twins—fully detailed models that ‘see’ like the final product would. Through simulation, engineers can:

Optical simulation has fundamentally altered how IR cameras are designed for today’s high-stakes environments. By replacing physical trial-and-error with virtual prototyping and quantitative validation, tools such as Ansys Speos empower engineers to optimize designs, suppress stray light, and maximize camera performance with speed and precision. For organizations seeking the clearest, most reliable IR data across industrial, aerospace, or automotive sectors, simulation-led camera design is not just an advantage—it is the new standard.