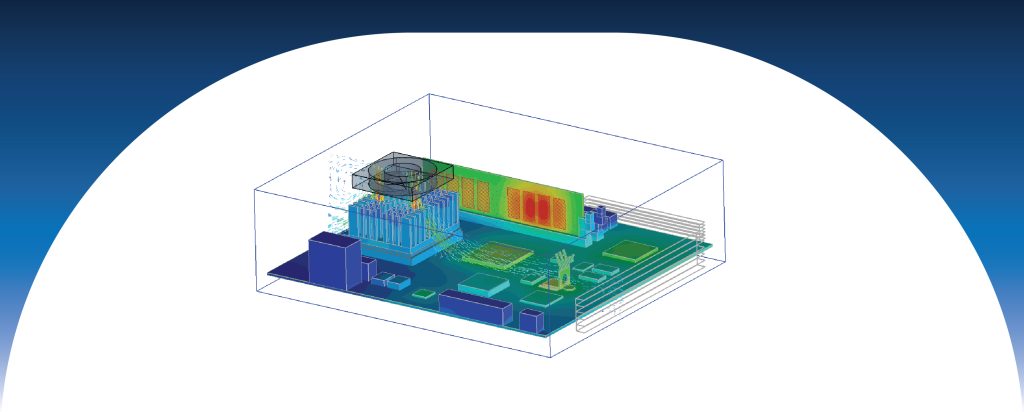

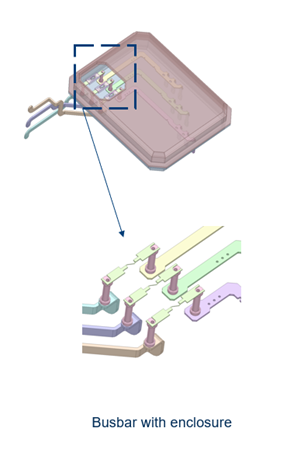

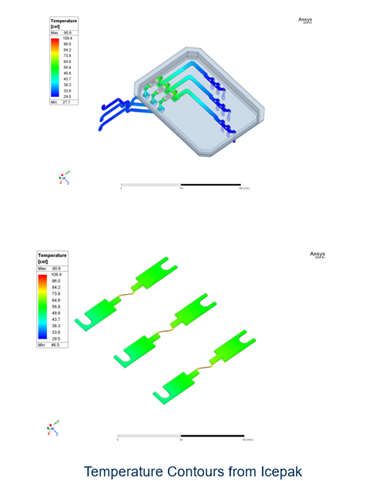

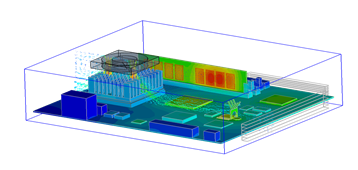

As electric vehicles (EVs) continue to evolve, efficient thermal management is essential for maintaining the performance, reliability, and longevity of critical power electronics components. Effective EV thermal management is crucial for ensuring the performance, reliability, and longevity of power electronics in electric vehicles. Components like PCBs, inverters, control units, and charging connectors generate significant heat, requiring advanced cooling solutions. This blog explores key thermal management strategies, including liquid cooling, optimized enclosure designs, and simulation-driven approaches to enhance efficiency and safety in EVs..

Inverters and DC-DC converters are essential in EV power systems, facilitating power conversion between the battery, motor, and auxiliary systems. These components operate at high switching frequencies, leading to substantial heat generation that must be effectively managed to ensure efficiency and longevity.

Effective thermal management is paramount for the performance, reliability, and safety of EV power electronics and control units. By addressing heat generation and dissipation through strategic material selection, optimized cooling techniques, and advanced enclosure designs, manufacturers can ensure that EVs operate efficiently even under demanding conditions. Ansys simulations play a crucial role in refining these strategies, helping engineers design and validate effective thermal solutions. As EV technology continues to evolve, advancements in thermal management will shape the future of electric mobility.

Interested in learning more? Join our webinar: ” Advanced Thermal Analysis and Simulation of Electronic Components and IC packages.” You can gain hands-on insights into Thermal Analysis and Simulation of Electronic Components and IC packages!