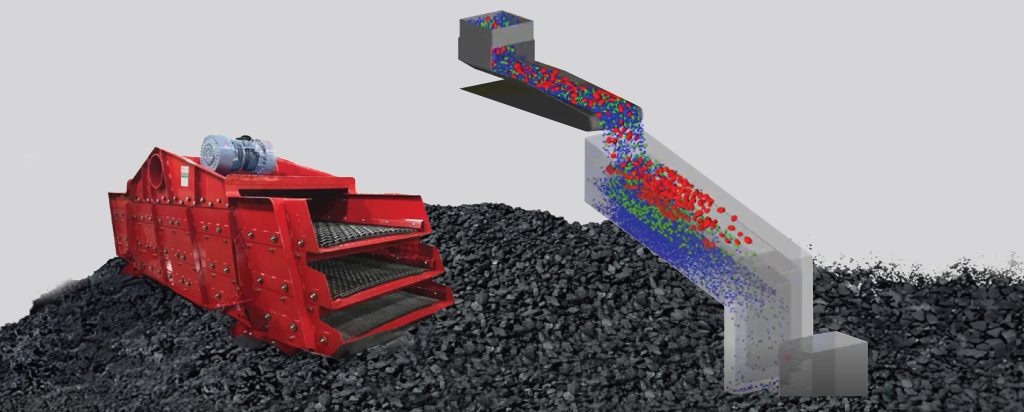

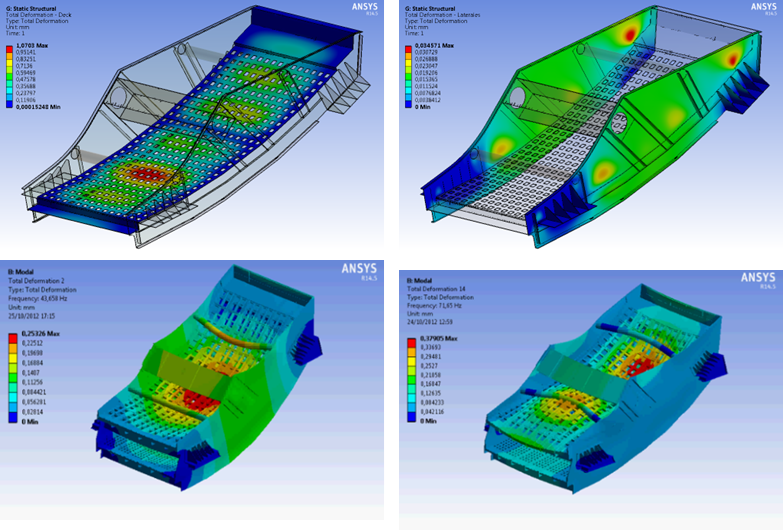

In the competitive mining industry, optimizing equipment performance isn’t just about increasing throughput—it’s about reliability, safety, and cost-effective design. One advanced approach that’s reshaping equipment development is the coupling of the Discrete Element Method (DEM) and Finite Element Method (FEM). In this blog post, we explore how DEM-FEM coupling—using Ansys Rocky for DEM and Ansys Mechanical for FEM—enhances the design and performance of vibrating screens, a critical piece of mineral processing equipment.

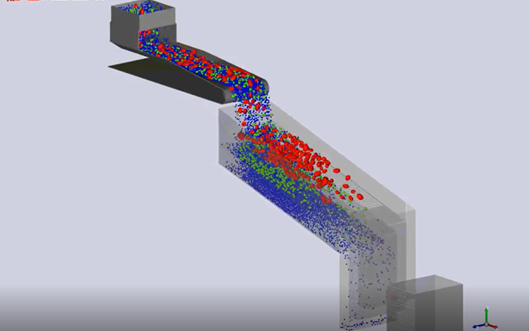

DEM is a powerful numerical tool that models individual particle interactions. Ansys Rocky, the industry-leading DEM simulation tool, accurately predicts the behavior of granular materials. It allows engineers to:

In a rapidly evolving mining industry, leveraging coupled DEM-FEM simulations is no longer optional—it’s essential. By using Ansys Rocky and Ansys Mechanical, companies can design vibrating screens that not only improve separation efficiency but also ensure structural durability and operational safety. This integration empowers engineers to innovate confidently, reducing both development costs and downtime.