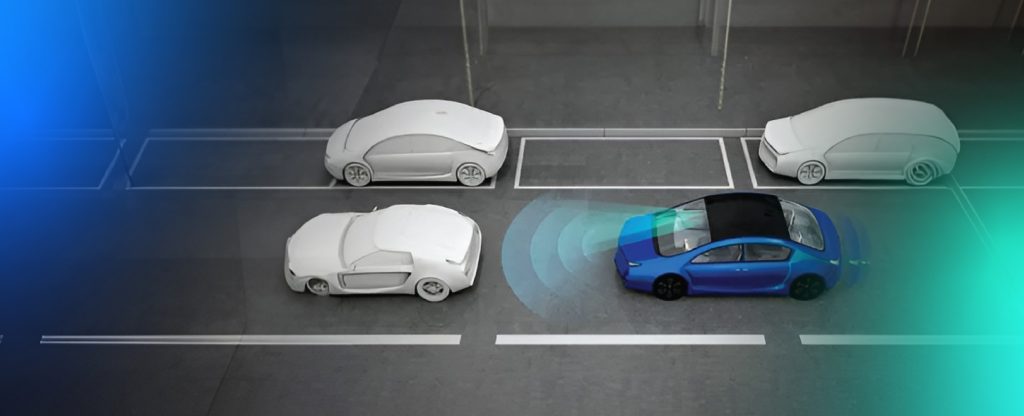

Autonomous Emergency Braking (AEB) is an advanced safety system designed to automatically apply the brakes when it detects an imminent collision, and the driver does not respond quickly enough. Using on-board sensors such as radar and cameras, AEB continuously monitors the road ahead and identifies potential hazards in real time. If the system calculates that a crash is likely, it can warn the driver and, if necessary, take autonomous action to decelerate the vehicle, helping avoid or mitigate the impact. AEB systems are now increasingly standard in modern vehicles, significantly improving road safety and reducing both the number and severity of accidents.

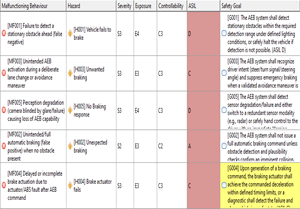

Functional safety software development for Autonomous Emergency Braking (AEB) systems is achieved by rigorously applying ISO 26262, the internationally recognized standard for automotive electrical and electronic systems. This framework ensures the identification, assessment, and mitigation of risks caused by system malfunctions, focusing on the entire vehicle life cycle. By establishing safety goals, analysing hazards, and defining Automotive Safety Integrity Levels (ASIL), ISO 26262 guides manufacturers in building robust AEB systems that reliably prevent or reduce serious collisions. Ultimately, compliance with ISO 26262 is essential for building consumer trust, meeting regulatory requirements, and protecting road users from critical failures in autonomous braking technologies.

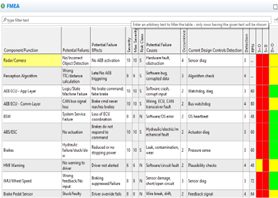

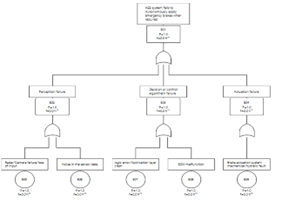

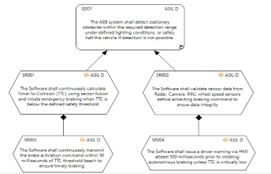

Functional safety approach in Ansys Medini Analyze on integrating HARA, FTA, and FMEA in a model-based environment, fully aligned with ISO 26262 standards. The tool ensures end-to-end traceability between SysML system models, requirements, and all safety analyses. This streamlines compliance, accelerates certification, and delivers consistent, efficient Functional safety software development workflows for complex automotive systems.

Connecting Design and Safety: A Smooth SCADE-to-Medini Integration Approach

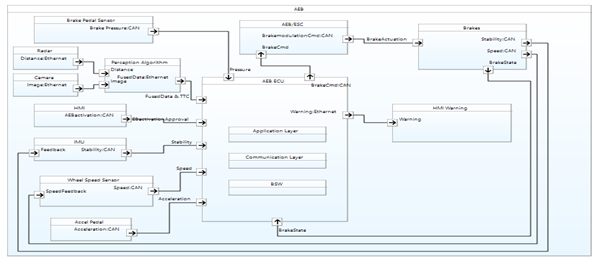

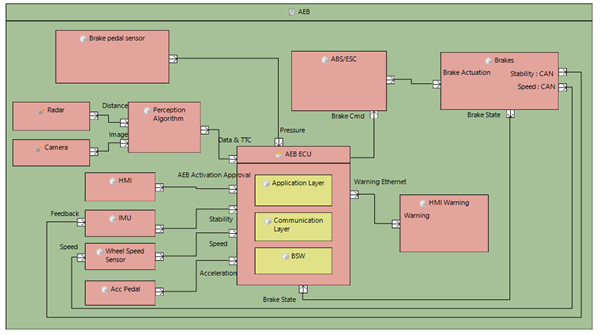

SCADE Architecture Model integrating with Ansys Medini Analyze involves using the Embedded System configuration in SCADE Architect to classify system elements such as Functions, Software Components, Hardware Components, Sensors, Actuators, and Processors. During translation, each configured block is mapped to an equivalent SysML-based element in Medini Analyze (e.g., Function → SysML Activity, SW Component → SysML Block with Software Unit category, HW Component → SysML Block with Hardware Part category). The integration is executed through the Import from SCADE Architect feature in Medini, which supports incremental updates via the Diff/Merge tool. In this import process, SCADE packages, block definitions, activities, ports, and connectors are automatically translated into SysML elements such as SysML Container Package, SysML Block, SysML Part, SysML Port, and SysML Connector. This ensures consistent naming and structural alignment, enabling engineers to proceed with safety analyses directly in Medini using the translated architecture model.

Architecture of AEB

Functional safety forms the backbone of reliable Autonomous Emergency Braking systems, ensuring vehicles can respond intelligently and safely in real-world conditions.

Through tools like Ansys Medini Analyze and structured methodologies such as HARA, FTA, and FMEA, engineers can design architectures that identify, evaluate, and mitigate risks at every level of the system.