Autonomous Emergency Braking (AEB) is one of the most crucial technologies shaping the future of safe and intelligent mobility. While functional safety lays the foundation for building reliable braking systems, bringing that intelligence to life requires more than just design—it demands precise software development and extensive virtual validation.

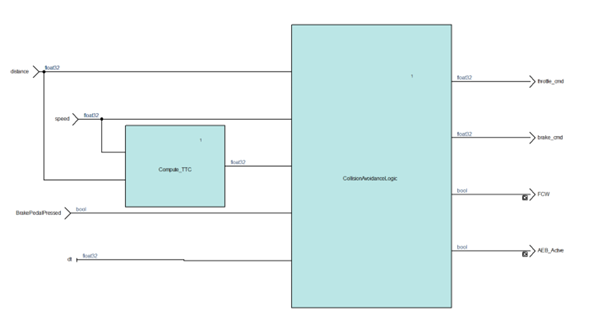

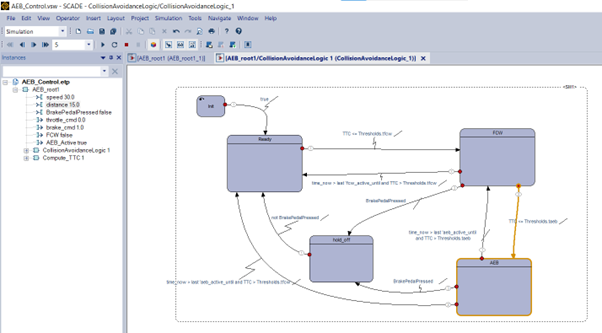

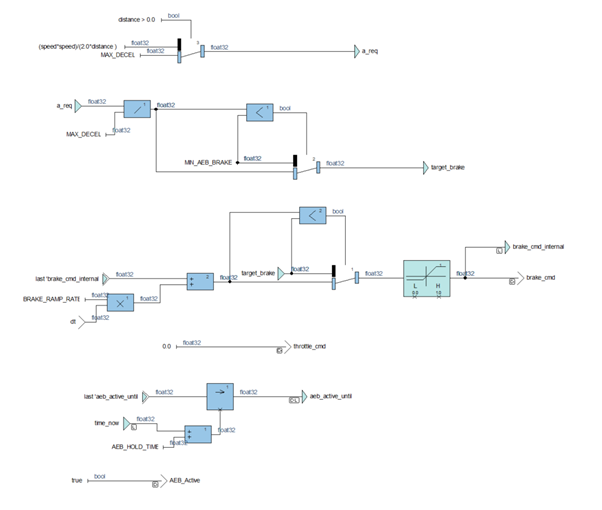

Fig3: Model based development using Ansys SCADE Suite

Once the algorithm is validated at the model level, SCADE allows you to generate ISO 26262-certified code that is functionally equivalent to the validated model. This means there’s no need for additional software-in-the-loop (SIL) comparisons or duplicative verification activities on the generated code. The model and the code are one and the same — helping you save time, reduce errors, and streamline certification.

Traditionally, AEB validation depended on physical proving grounds, while effective, these tests are expensive, time-consuming, and limited in their ability to cover edge cases. The shift toward digital validation has reshaped how OEM’s approach ADAS development-With virtual testing becoming a cornerstone of modern safety system validation.

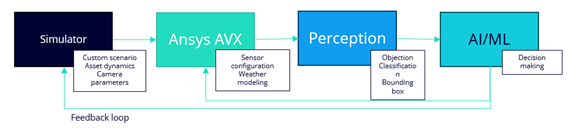

Ansys AVxcelerate sets itself apart with true physics-based simulation, modeling how light, radar waves, LiDAR beams, and thermal radiation interact with materials, weather, and lighting conditions. For AEB development, this realism is essential, as accurate perception directly influences braking decisions and safety outcomes.

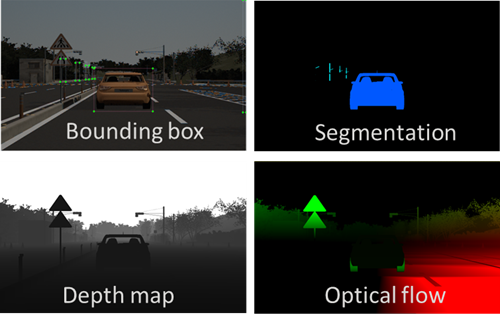

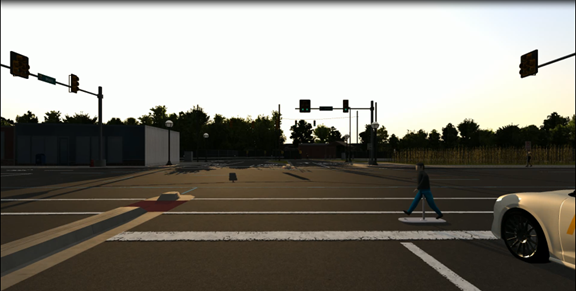

Fig: Ground Truth Data from Avxcelerate

The AEB validation workflow begins with scenario setup, where an ego vehicle equipped with AEB logic is placed in a dynamic, orchestrated virtual environment. Other vehicles and pedestrians are added as active participants, and environmental factors like lighting and weather are precisely controlled.

The virtual camera is configured with adjustable FoV, resolution, and shutter parameters. Its outputs — including RGB frames, segmentation masks, and bounding boxes — form the perception input for AEB logic validation. The algorithm is then tested using Time-to-Collision (TTC) metrics, with braking events triggered when collision risk crosses the threshold. Failures such as delayed braking or false detections are logged for analysis.

As the automotive industry accelerates toward autonomy, virtual validation is no longer optional — it’s essential. By combining Ansys SCADE’s ISO 26262-certified model-based software development with Ansys AVxcelerate’s physics-based simulation, OEMs can bridge the gap between design and reality.

You read it in theory. Now see it practically. Watch Full Webinar Now