As engineers, achieving accurate simulation results is paramount to the success of any project. When it comes to finite element analysis (FEA), Ansys Mechanical in 2025R1 offers powerful tools for overcoming some of the most challenging aspects of simulation—mesh convergence, local mesh refinement, and stress singularities. In this blog, we’ll explore how these concepts can be effectively handled in Ansys 2025R1, helping engineers optimize simulations and ensure reliable results.

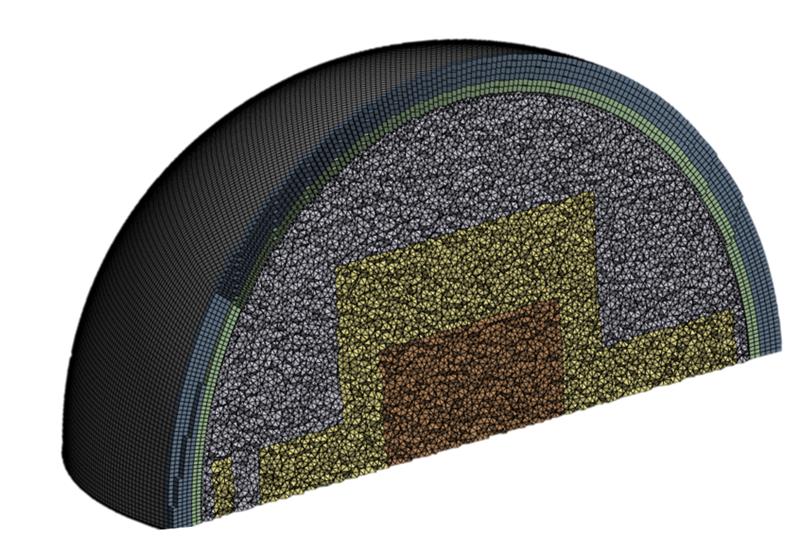

Mesh convergence is the process of refining the mesh until the solution stabilizes. In FEA, the quality of the mesh directly impacts the accuracy of results. A finer mesh can produce more precise solutions, but at the cost of increased computational time and resources. Therefore, understanding when to stop refining the mesh is crucial.

Practical Tip: When performing convergence tests, pay attention to important quantities such as displacements, stresses, and strains. The goal is to ensure that the results don’t change substantially when the mesh is refined further. This guarantees that your solution is accurate and optimized.

In Ansys 2025R1, local mesh refinement is easy to implement. With advanced tools like adaptive meshing, Ansys automatically refines the mesh in areas of high gradient, such as around holes, notches, or sharp corners, where stress concentrations are most likely to occur. By refining the mesh only in these specific areas, engineers can improve accuracy without unnecessarily inflating the computational cost for less critical regions.

Why It Matters: Local mesh refinement not only ensures better accuracy but also optimizes computational resources—making it a time-efficient solution. Additionally, it allows for better handling of complex geometries like fillets and sharp edges, where stress analysis is crucial.

In Ansys 2025R1, advanced techniques are available to identify and mitigate stress singularities. The software offers tools like remeshing and stress smoothing, which help to better represent stress fields around singularities. By refining the mesh at singular points or applying stress smoothing algorithms, engineers can minimize the effects of these numerical artifacts.

Practical Tip: When analysing stress singularities, it’s essential to verify whether these high values are real or just numerical errors. In many cases, adjusting the mesh around singularities or using local refinement strategies can significantly reduce erroneous stress peaks.

To get the most out of Ansys 2025R1 when dealing with mesh convergence, local mesh refinement, and stress singularities, follow these best practices:

In Ansys Mechanical 2025R1, tackling mesh convergence, local mesh refinement, and stress singularities has never been easier. The software offers powerful tools to handle these challenges efficiently, ensuring that engineers can achieve both accurate and computationally feasible results. By implementing best practices and leveraging the software’s advanced features, simulation results can be made both reliable and optimized for the most complex engineering problems.

For further assistance or to explore how Ansys 2025R1 can solve your simulation challenges, contact the team at CADFEM India today!