The electric vehicle (EV) industry is witnessing intense competition from established manufacturers to new startups, all striving to capture the market by offering superior products. The race to dominate the EV sector demands shorter product development cycles, compelling manufacturers to design best-in-class powertrains with maximum efficiency, reduced costs, and lower weight. However, designing and optimizing EV powertrains presents several challenges from the view of energy management and thermal regulation to real-world performance validation.

A more efficient powertrain directly translates to extended vehicle range, a key factor influencing consumer adoption. However, one of the biggest challenges in EV adoption is charging speed, as it is nowhere near as quick and convenient as refuelling an internal combustion engine vehicle. Reducing charging time and improving vehicle efficiency are critical hurdles that the automotive industry is actively addressing through research and development.

This blog explores key challenges in EV powertrain technology and how Ansys ConceptEV empowers manufacturers to overcome these obstacles effectively.

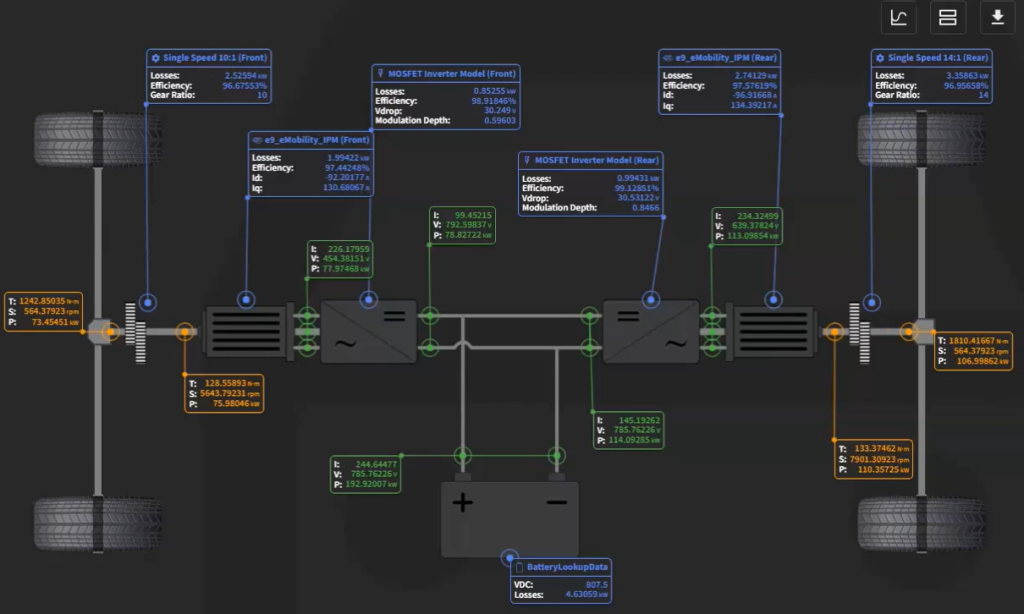

Ansys ConceptEV is a specialized cloud-based design and simulation platform for the early-stage development of electric powertrains from a system-level perspective. It provides a collaborative environment where design teams can fine-tune the interactions between different powertrain components, ensuring maximum efficiency and performance.

Simulated performance of a dual-motor EV powertrain across the WLTP drive cycle, showing predicted driving range and energy efficiency

ConceptEV can seamlessly integrate with other Ansys tools to enhance EV powertrain design. It works with Ansys optiSLang for design space exploration, Ansys Motor-CAD for multiphysics motor simulations, and Ansys Maxwell for advanced electromagnetic field analysis. Additionally, ConceptEV supports third-party tool integration and custom workflow automation through its Python API, enabling manufacturers to streamline their development processes.

With its advanced simulation capabilities, seamless tool integration, and AI-powered predictive analysis, ConceptEV empowers automakers to build smarter, more efficient, and future-ready electric vehicles while reducing costs and accelerating time-to-market.

As EV technology evolves, manufacturers that leverage cutting-edge simulation tools like Ansys ConceptEV will lead the charge in creating the next generation of high-performance, sustainable electric vehicles.