Static mixers are vital tools in engineering and fluid mechanics, allowing efficient mixing of fluids without the need for moving parts. By leveraging Computational Fluid Dynamics (CFD) simulations in Ansys Fluent, engineers can optimize static mixer designs, predict performance, and enhance industrial processes. This article delves into the role of Ansys Fluent in analyzing the mixing of two immiscible fluids in a static mixer and highlights its transformative impact on fluid mixing workflows.

Ansys Fluent is a powerful CFD software that allows engineers to simulate and analyze fluid behavior within static mixers. By modeling complex mixing processes, Ansys Fluent offers invaluable insights that are difficult to achieve through traditional experimental methods. Key advantages of using Ansys Fluent for mixing analysis include:

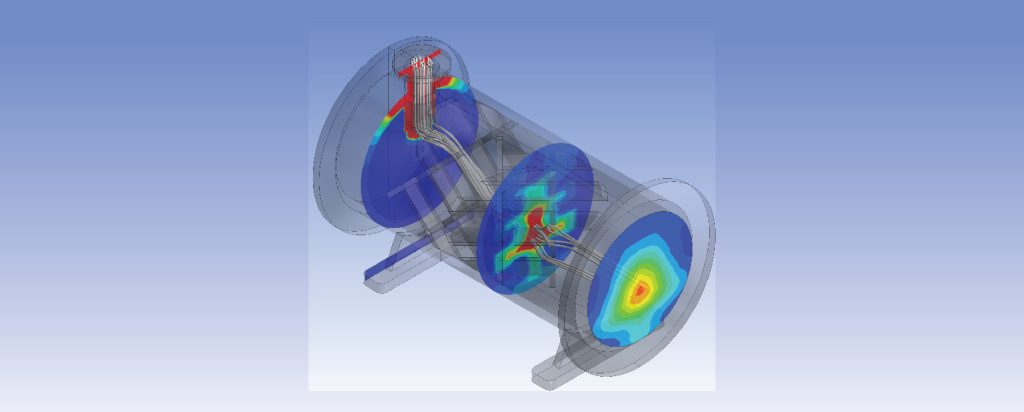

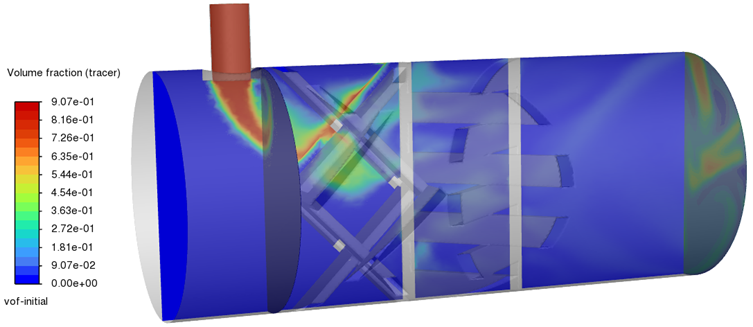

Contour for volume fraction of tracer on sectional plane

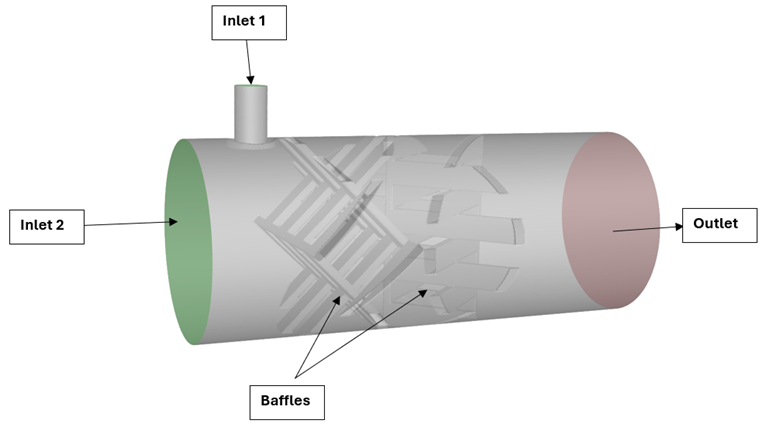

Geometry with boundary conditions

Simulating different operating conditions—such as flow rates, viscosities, and fluid properties—in Ansys Fluent ensures reliable performance predictions. This helps engineers design mixers that meet real-world requirements.

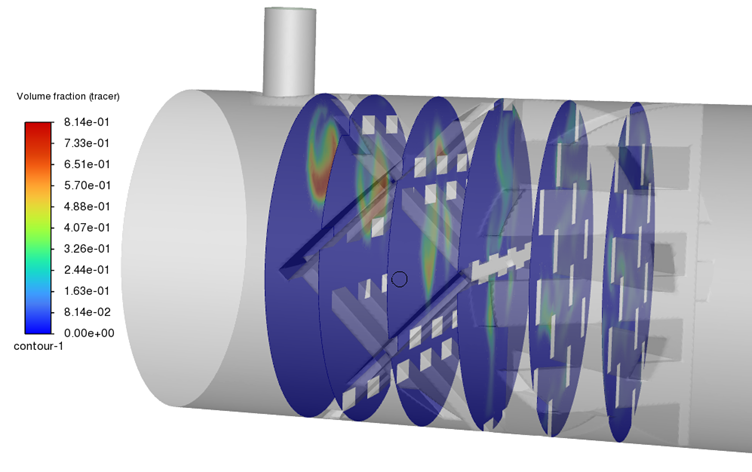

Contour for volume fraction of tracer on cross sectional planes near baffles

Ansys Fluent can be applied to a wide range of static mixer design and optimization scenarios, including:

Ansys Fluent assesses the impact of scaling up static mixer designs, ensuring that performance remains consistent across different operational scales. Engineers can also optimize process parameters to maximize efficiency.

Ansys Fluent revolutionizes the analysis and optimization of static mixers by providing detailed insights into fluid behavior and mixing efficiency. From simulating immiscible fluid mixing to optimizing heat transfer and mass transfer processes, Ansys Fluent empowers engineers to tackle complex challenges and achieve superior designs.