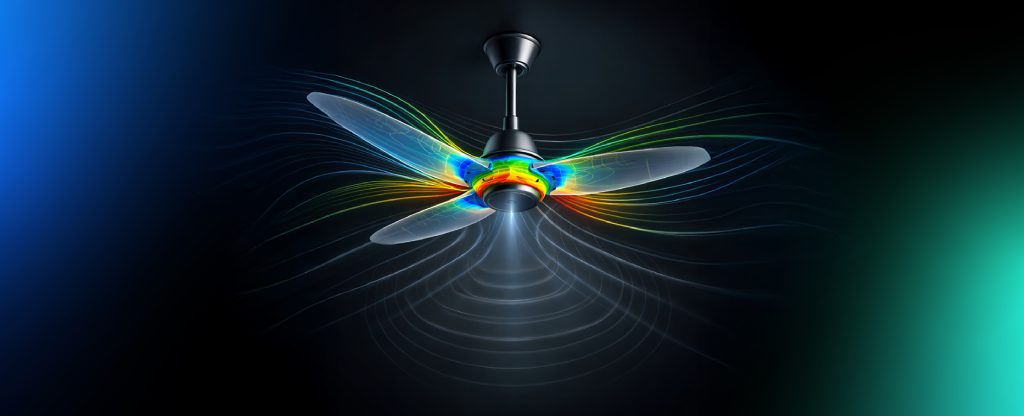

In Part 1 of this blog series, we explored how Ceiling fan airflow simulation using Ansys Fluent enables accurate airflow prediction and IS 374-compliant performance assessment for ceiling fans — helping engineers optimize designs for better energy efficiency and air delivery without costly physical prototyping.

In Part 2 below, we dive deeper into fluid-structure interactions, blade optimization, acoustics, and simulation automation to complete the digital design workflow.

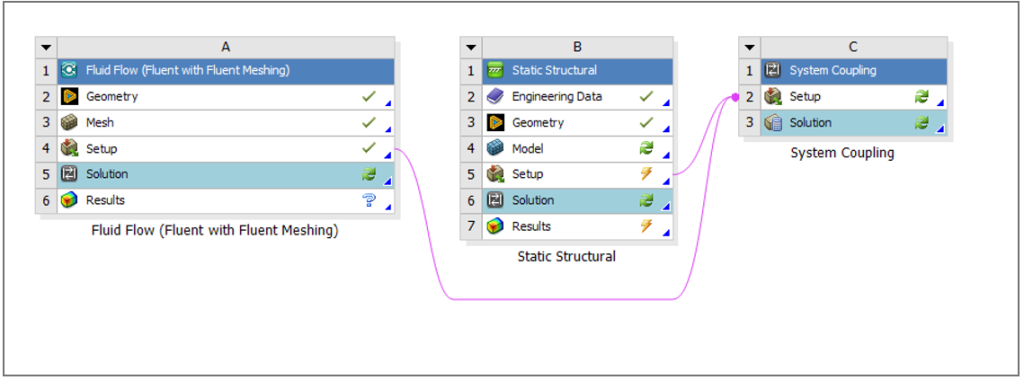

During operation, ceiling fan blades are not only subjected to aerodynamic loads but also to self-weight and centrifugal forces. If blade design lacks structural capacity, these loads can cause undesired deformation or failure.

Under fluid loading, blades deform — changing their shape and, consequently, the airflow patterns they generate which directly impacts ceiling fan airflow simulation accuracy. This creates a coupled behavior where the modified flow affects further blade deformation, making it critical to capture these interactions early in the design cycle.

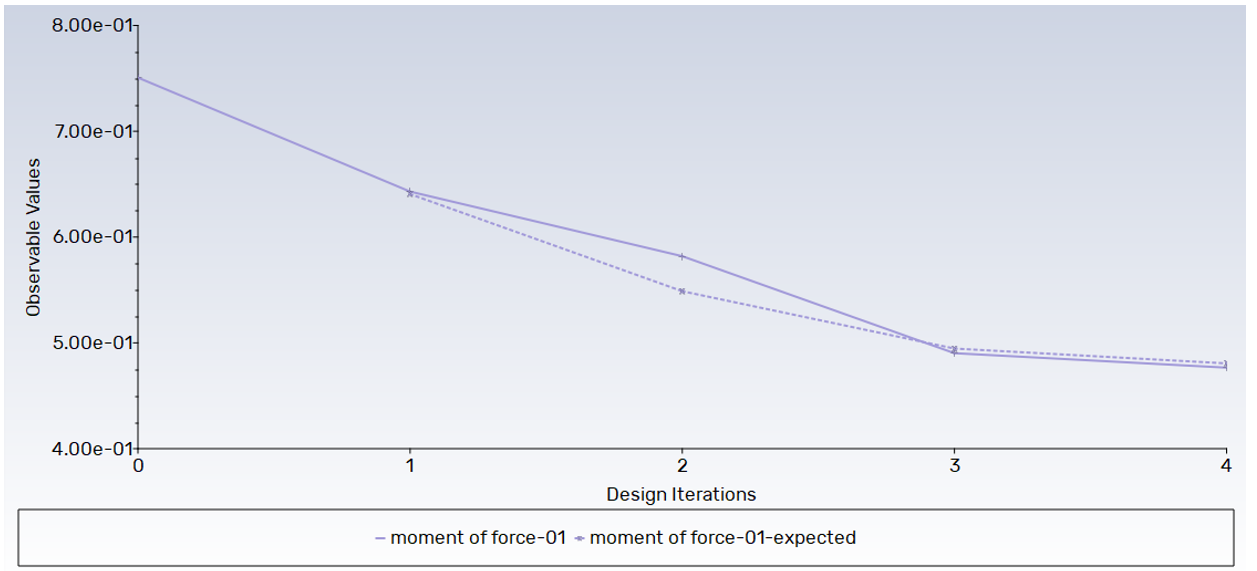

Designers seek blade profiles that maximize airflow and efficiency while maintaining structural integrity making ceiling fan airflow simulation essential during early design stages. Traditional parametric optimization (e.g., DOE with Ansys optiSLang) can require significant computational resources.

In addition to gradient-based methods, multi-objective parametric optimization (e.g., with Ansys optiSLang) enables systematic exploration of geometric variations against performance goals. These studies can reveal trade-offs between torque, air delivery, and structural constraints to guide robust blade designs.

As simulation workflows grow more complex, automation becomes essential for productivity. IS 374 air delivery testing must be conducted for multiple blade designs, making manual setup repetitive and time-consuming.

Using PyFluent, the entire IS 374 simulation workflow can be automated—from model setup and execution to post-processing—ensuring consistency while significantly reducing overall analysis time.

Designing an efficient and reliable ceiling fan requires more than optimizing airflow alone. By integrating fluid–structure interaction, blade optimization, aeroacoustics, and simulation automation, engineers can realistically evaluate blade deformation, improve performance, reduce noise, and accelerate design validation through advanced ceiling fan airflow simulation. Together with the aerodynamic insights from Part 1, these advanced Ansys simulation techniques enable a holistic, physics-based approach to ceiling fan design, supporting better engineering decisions with reduced reliance on physical prototyping.