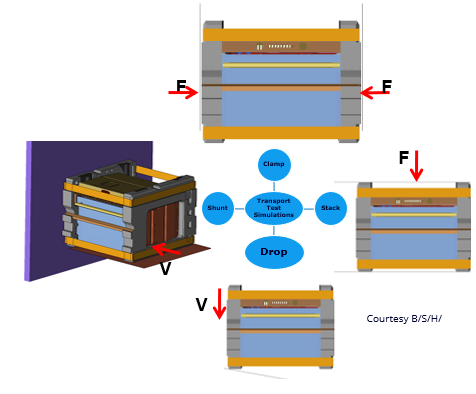

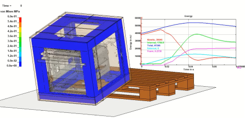

This is where Virtual Transport Test Simulation using LS-DYNA Packaging Simulation revolutionizes the process. By simulating real-world transit conditions digitally, packaging engineers can predict failures, optimize materials, and design smarter packaging earlier in the development cycle.

To ensure safety and reliability, global standards like ASTM, ISTA, ISO, and PATT specify detailed testing procedures. These tests evaluate:

This balancing act between cost, protection, and material sustainability demands a modern approach—one that LS-DYNA Packaging Simulation delivers effectively.

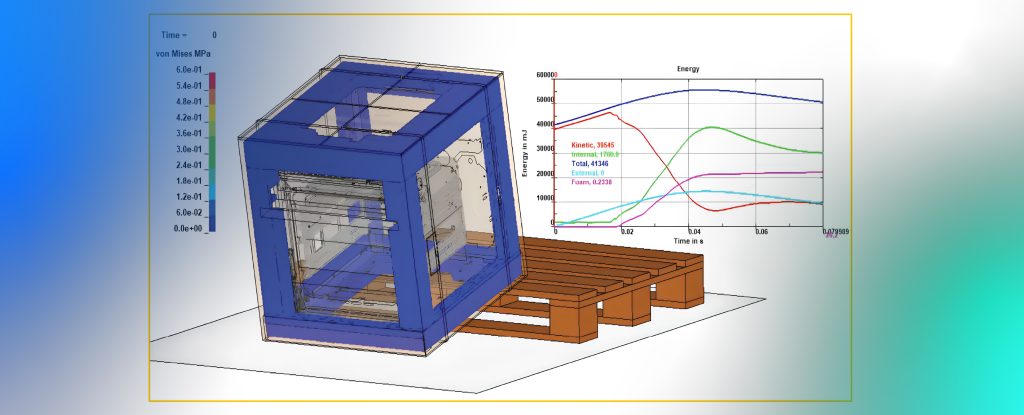

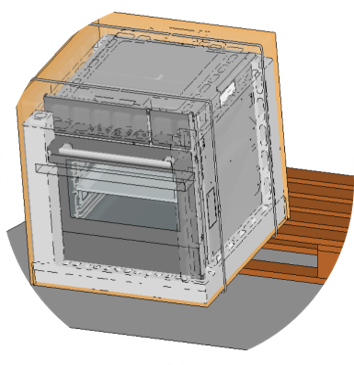

Engineers model the appliance, EPS or corrugated protectors, and secondary packaging elements.

LS-DYNA supports advanced material models for:

Engineers analyze:

This enables early design corrections without physical prototypes.

Corrugated board is increasingly preferred due to its recyclability and reduced environmental footprint. LS-DYNA supports sustainability-driven optimization by enabling engineers to fine-tune:

Optimization techniques like topology optimization, volume minimization, and compliance reduction ensure material is used only where structurally necessary.

This leads to lightweight yet robust packaging that meets ASTM/ISTA standards without excess material.

Companies using LS-DYNA for virtual transport validation report significant improvements:

For manufacturers of home appliances and consumer goods, LS-DYNA Packaging Simulation is not just a simulation tool—it is a strategic enabler for smarter, lighter, and greener packaging.