Permanent magnets lie at the heart of modern electromechanical systems—from electric vehicles and wind turbines to MRI machines and high-speed actuators. The accuracy of electromagnetic simulation, particularly Magnet modelling, is key to predicting performance, minimizing losses, and ensuring long-term reliability. Boost accuracy in electromagnetic design with Ansys Maxwell magnet modeling, from static fields to demagnetization and magnetostriction.

Ansys Maxwell, a flagship low-frequency electromagnetic solver, offers a comprehensive platform for modelling magnets in both isolated and system-level contexts. This blog explores these techniques with a focus on:

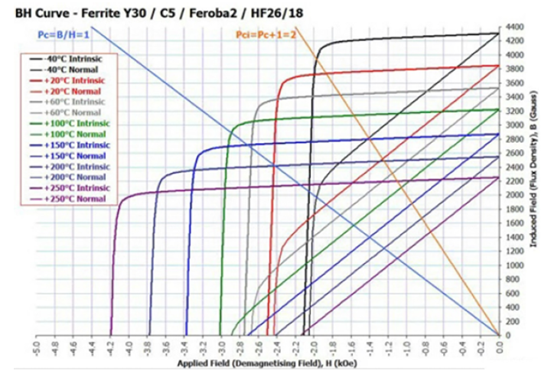

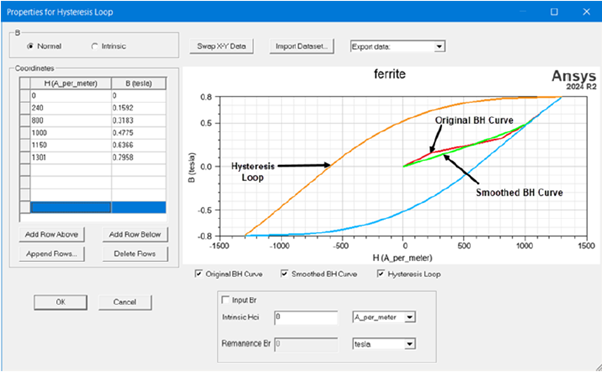

Modern magnetic systems rarely operate in a truly static regime. Motors switch, actuators move, and field conditions fluctuate continuously. Maxwell’s transient solver captures these dynamic behaviours by solving Maxwell’s equations in the time domain. This becomes essential when simulating the start-up of a motor, analysing back-EMF generation, calculating eddy current losses in magnets, or evaluating time-dependent torque profiles. For devices involving motion, Maxwell allows full electromechanical coupling, simulating both linear and rotational movements with real-time force extraction and position-dependent field updates.

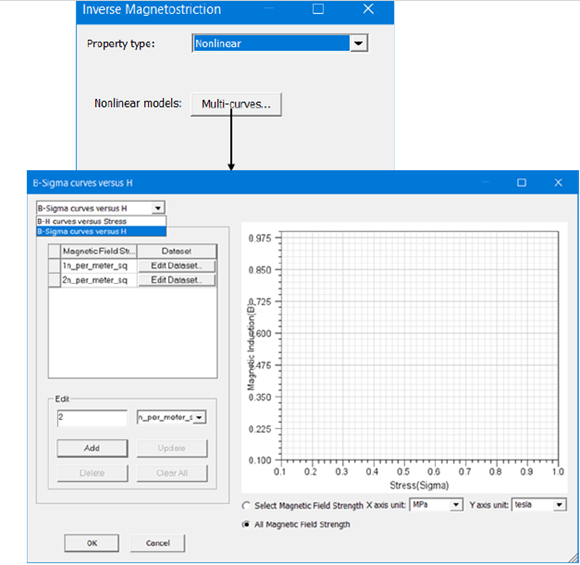

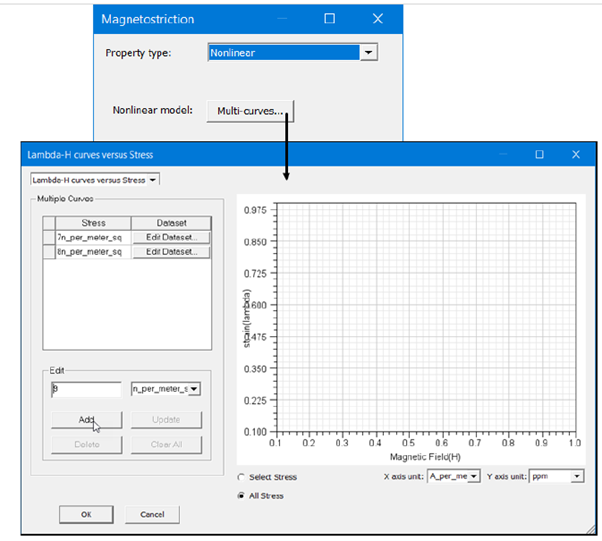

Magnetostriction—deformation due to magnetic domain alignment—can lead to noise, vibration, or stress in magnetic systems. This is especially relevant for applications like transformers and high-speed motors. Maxwell enables modelling of magnetostriction effects by coupling electromagnetic simulations with structural solvers like Ansys Mechanical. The inverse effect, where mechanical stress influences magnetic properties, is also supported and is valuable in the design of sensors, actuators, and energy harvesters.

What truly sets Maxwell apart is its ability to bridge electromagnetics with mechanical and thermal domains. Magnetostrictive effects — where materials physically deform in response to magnetic fields — can be extracted from electromagnetic simulations and passed into Ansys Mechanical. This enables users to study structural deformation, stress, and even vibration caused by magnetic excitation. When further coupled with CFD tools like Ansys Fluent or Icepak, one can model how thermal gradients influence magnet behavior, including reductions in remanent flux density and susceptibility to demagnetization.