Ceiling fans are essential for home ventilation, and optimizing their design for peak performance and energy efficiency is more important than ever. This blog explores how Ansys Fluent simulation is revolutionizing ceiling fan design, enabling engineers to digitally model airflow and fine-tune specifications without costly physical prototypes. Ceiling fans remain one of the most widely used air ventilation solutions in households due to their energy efficiency compared to air conditioning systems. Consisting primarily of a motor and rotating blades, ceiling fans work by displacing air to create airflow. As their use continues to grow, improving the energy efficiency of ceiling fans is becoming increasingly important—both for environmental and regulatory reasons.

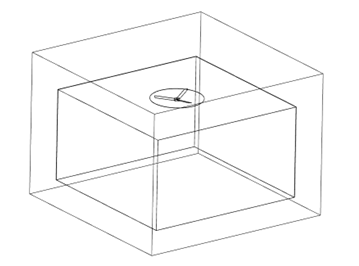

Fig 1 : Simulation domain

Traditionally, testing different blade designs requires physical prototyping, which can be time-consuming and costly. With Ansys Fluent, digital prototypes allow engineers to simulate and validate blade designs efficiently.

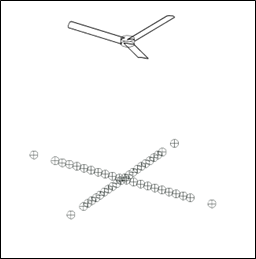

Fig 2 : Velocity measurement location

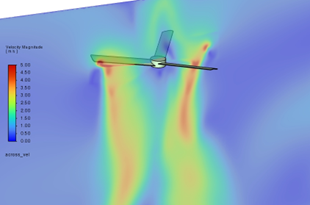

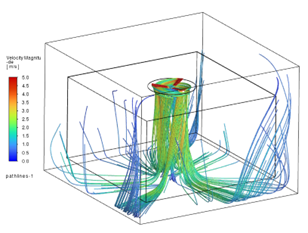

Ansys Fluent is a leading CFD (Computational Fluid Dynamics) software that enables detailed simulation of fluid, thermal, and chemical behaviours. For ceiling fans:

Beyond estimating air delivery, Ansys Fluent simulations provide valuable data:

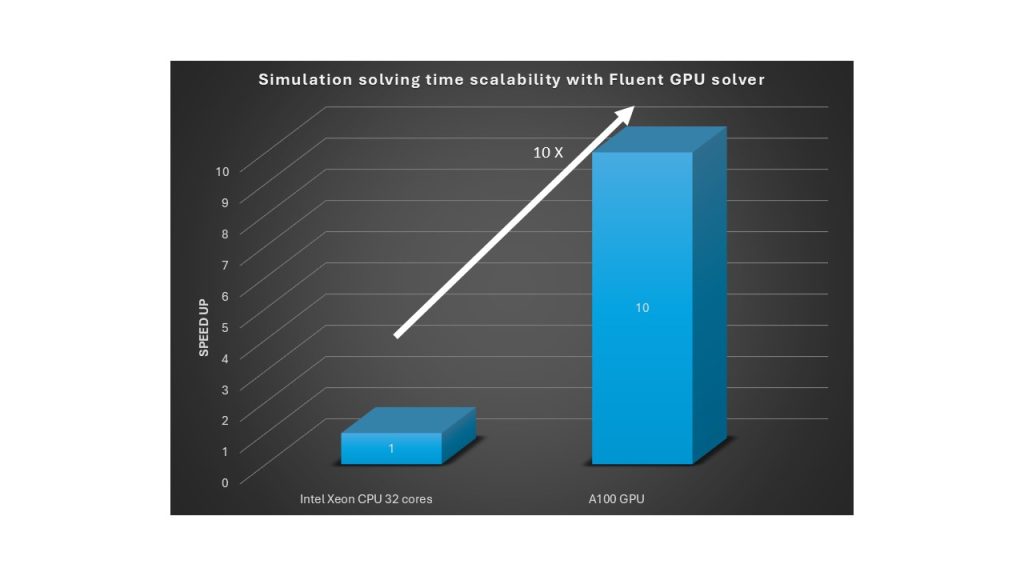

IS374 test simulations usually takes couple of hours of simulation time with parallel CPU cores but now with the introduction of Fluent GPU solver a ~10X scalability can be observed which can bring down the simulation time to couple of minutes. Such scalability along with Ansys optimization technology can accelerate the blade design optimization tremendously.

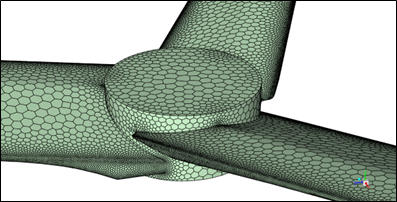

With the advancement in technology complex blade profiles are being considered for analysis. Clean up of such complex blade geometries for simulation can be challenging & time consuming. Fault-tolerant meshing within Ansys fluent meshing can capture such complex geometry using wrapper technology. Dirty blade geometries with slivered faces, gaps or overlapping geometry can be easily captured with the various options within FTM like leakage threshold, local wrapper sizing & intersection loop.

Key Features and Benefits:

In the next part of this blog series, we’ll explore:

Ultimately, the power of Ansys Fluent simulation provides a transformative approach to ceiling fan design, promising quieter, more efficient, and sustainable ventilation solutions for the future. Stay tuned to learn how simulation is powering the next generation of quiet, efficient, and sustainable ceiling fans.